Advanced Process Technology

TA Talent Industries utilizes an advanced intelligent process management system in its production process. This includes the installation of PLC electrical control systems, enabling remote maintenance, data collection, and data preservation through IoT technology, effectively improving production efficiency, and reducing power consumption.

The company is equipped with the latest development of medium to high frequency induction melting furnaces. These furnaces have a melting efficiency of 535kWh/ton at a target temperature of 1480°C, with an energy-saving rate of up to 23% compared to older equipment, thereby reducing CO2 emissions.

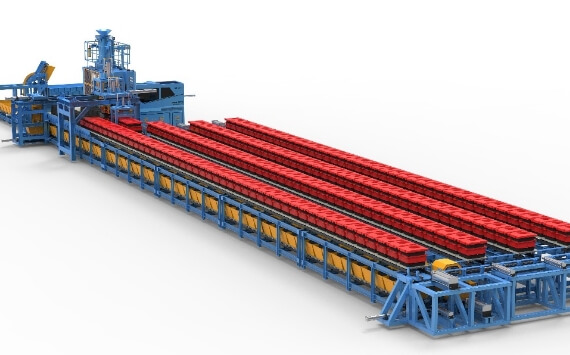

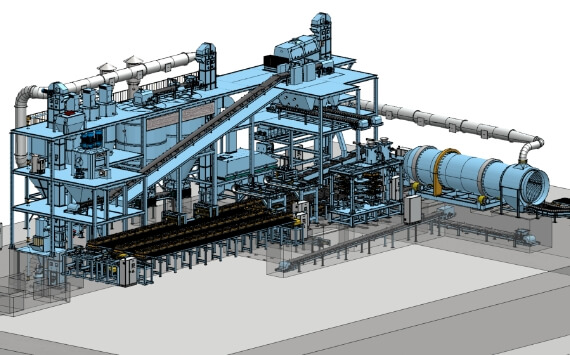

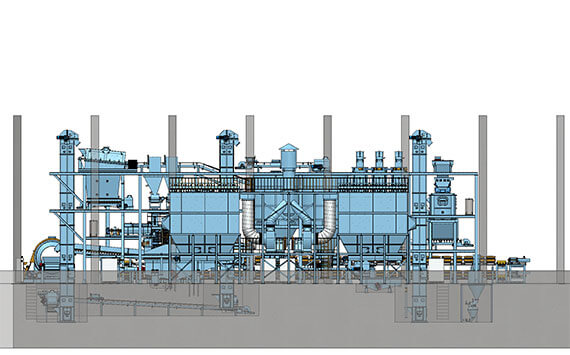

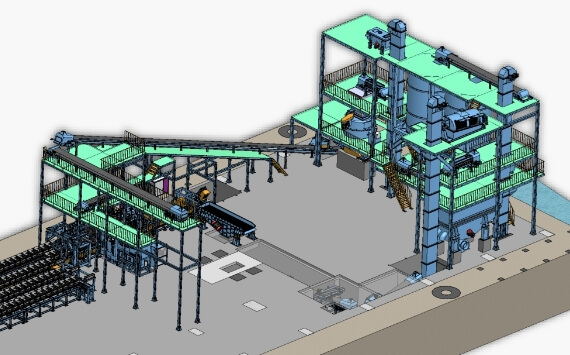

On-site Production Line Equipment

TA Talent Industries' production lines are equipped with state-of-the-art automated devices, ensuring optimal efficiency and precision. These devices streamline the loading and unloading process of flasks and the placement of chills. They also provide a user-friendly interface to monitor production status and equipment operation, resulting in enhanced production efficiency and product quality.

This equipment consists of a planetary frequency conversion sand mixer, a quantitative sand-adding device, and a quantitative auxiliary material conveying device. It has the ability to automatically detect the quality of molding sand and automatically supplement auxiliary materials or moisture. This technology enhances the quality of the molding sand while also decreasing production expenses.

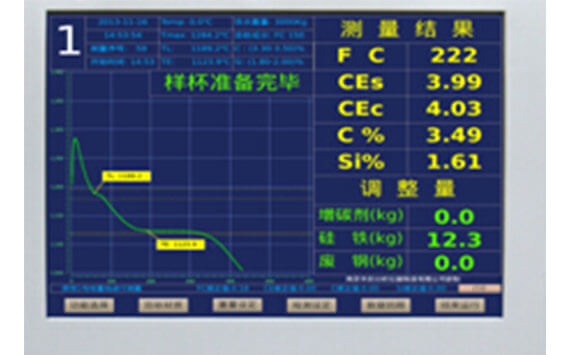

Inspection and Quality Control Equipment

TA Talent Industries employs advanced inspection equipment, such as spectrometers, carbon-silicon analyzers, metallographic microscopes, and HB Brinell hardness testers, to ensure product quality meets international standards.