TA Talent Industries' Corporate Responsibility

The Leader of Green Transformation: Guiding Industries Towards a Sustainable Future

TA Talent Industries' Path to Sustainable Development at TA Talent Industries, we understand that the success of our business is closely tied to social responsibility and environmental protection. Leading the way in the precision casting industry, our dedication is focused on advancing towards a more environmentally friendly and sustainable future.

-

• Application of Green EnergyWe actively incorporate green energy by installing photovoltaic solar panels on the roofs of our facilities. These panels not only reduce our dependence on traditional energy sources but also decrease our operational carbon emissions, reflecting our commitment to energy conservation and emission reduction.

-

• High-Efficiency Production TechnologyWe use advanced medium to high frequency induction melting furnaces to enhance energy efficiency while reducing energy consumption and carbon emissions. Our intelligent sand recycling technology minimizes waste production in the manufacturing process, achieving efficient resource utilization.

-

• Eco-Friendly Production ProcessEvery step, from the selection of raw materials to the final product production, is aimed at minimizing environmental impact. Our materials and production processes meet international environmental standards, ensuring our products are earth-friendly without compromising quality or performance.

-

• Social ResponsibilityBeyond environmental care, TA Talent Industries actively takes on social responsibility. We collaborate with local communities, investing in education and social welfare projects, and provide a safe, healthy working environment for our employees.

TA Talent Industries Co., Ltd. believes that through these efforts, we can not only enhance our business performance but also contribute to the sustainable development of society and the planet.

They are not just accepting the challenge but actively turning it into an opportunity for action. The company is dedicated to supporting and reaching the goal of achieving net-zero carbon emissions by 2050, utilizing a range of innovative and environmentally friendly initiatives, showcasing a strong dedication to sustainability. Environmental Contribution: Aligning with the 2050 Net-Zero Carbon Policy through Installation of Photovoltaic Solar Panels.

-

• Implementation OverviewThe company intends to set up photovoltaic solar panels on factory roofs to maximize the use of renewable energy, with the goal of decreasing the company's carbon footprint.

-

• Installation ScaleThe planned solar panels will cover approximately 1,428 square meters of roof area, making it a substantial energy generation base.

-

• Energy ProductionThe total installed capacity of these solar panels is projected to reach 288 kWp, producing approximately 340,983 kWh of electricity annually.

-

• Carbon Reduction BenefitsAnticipated annual reduction of approximately 168 tons of carbon emissions, significantly aiding in the fight against climate change. These cutting-edge environmental initiatives showcase the company's dedication to sustainability and reinforce its reputation as a responsible and forward-thinking organization. Furthermore, these actions assist the company in boosting energy efficiency, cutting operational expenses, and strengthening its eco-friendly reputation in the international market, showcasing TA talent Industries' commitment to environmental protection and sustainable growth.

The essential in addressing global climate change and resource scarcity. Businesses have a significant responsibility to pursue eco-friendly and efficient solutions.

TA talent Industries Co., Ltd. is not simply involved in this shift, but is actually at the forefront. Our focus is on achieving energy efficiency and reducing carbon emissions, particularly in the crucial casting process.

We are dedicated to innovating and upgrading equipment to minimize our carbon footprint, showcasing our strong dedication to environmental protection.

TA talent Industries has made substantial progress in energy efficiency and reducing carbon emissions by focusing on key equipment, such as the melting furnace, used in the casting process. Revolutionizing High-Efficiency Melting Furnaces.

-

Technological Improvement

Utilizing cutting-edge technology from a local Taiwanese R&D team, the company has upgraded its equipment to include high-efficiency medium to high frequency induction melting furnaces. -

Specifications and Performance

Utilizing cutting-edge technology from a local Taiwanese R&D team, the company has upgraded its equipment to include high-efficiency medium to high frequency induction melting furnaces. -

Energy Efficiency

The new furnaces boast an impressive annual energy-saving efficiency of up to 23%. -

Carbon Reduction Effect

By saving energy, it is estimated that 448,000kWh of electricity can be saved annually, which is equivalent to reducing approximately 221.8 tons of carbon dioxide emissions. This initiative showcases the company's dedication to environmental protection while also focusing on improving production efficiency and cutting operational costs. Through the implementation of these high-efficiency energy-saving devices, TA talent Industries demonstrates its innovative prowess in environmental technology, solidifying its standing as a forward-thinking and eco-conscious leader in the manufacturing sector.

Crucial for advancing towards sustainable development. Utilizing innovative technologies and optimizing resource utilization are essential.

TA talent Industries Co., Ltd. has made significant strides in sand recycling, demonstrating a strong commitment to environmental protection and resource reuse.

This not only demonstrates the company's dedication to environmental protection but also underscores the drive to accomplish green development in the manufacturing sector. Revolutionary Sand Recycling Technology.

-

• Intelligent Recycling SystemUtilizing cutting-edge intelligent sand recycling equipment to efficiently mix and stir new sand, coal powder, and clay, guaranteeing consistent and top-notch molding sand.

-

• Efficient Molding and Separation ProcessAn efficient molding and separation process involves vibrating the sand after molding to separate the casting blanks from the sand, ensuring effective separation.

-

• Environmental and Resource ReuseHe used sand, after magnetic separation, is reused, achieving a recycling rate of up to 95%. This not only reduces the demand for new sand but also significantly decreases waste production. Ecological Benefits and Savings.

-

• Resource SavingsBy implementing this recycling method, TA talent Industries effectively minimizes the requirement for new sand resources, promoting resource circulation.

-

• Reduced Environmental ImpactBy efficiently reusing used sand, waste emissions are decreased, which in turn reduces environmental impact.

-

• Enhanced Economic BenefitsBy efficiently reusing used sand, waste emissions are decreased, which in turn reduces environmental impact.

TA Talent Industries Co., Ltd. shows dedication to sustainable development and highlights its innovative environmental technology in the manufacturing sector through these initiatives. Implementing these cutting-edge technologies not only boosts the company's competitive edge but also serves as a model for the industry's shift towards environmental sustainability.

Along with the current global environmental challenges, TA talent Industries Co., Ltd. is setting a standard in the manufacturing industry for environmental protection and resource efficiency. The company's implementation of innovative measures showcases its dedication to environmental protection and its continuous efforts to improve production efficiency. These are the primary environmental initiatives:

-

• Recycling and remeltingThe company focuses on recycling metal materials, pig iron, and scrap steel by melting them in a medium- to high-frequency induction melting furnace, thereby improving resource utilization efficiency.

-

• Effective Separation and Recycling SolutionsOnce melted, the molten iron is poured into sand molds to cool. Once the cast blanks are separated from the sand, the castings and gates are efficiently separated.

-

• Thorough Recycling UtilizationThe process achieves a high rate of recycling and reuse of scrap iron.

-

• Reduced Environmental ImpactBy implementing an effective scrap iron recycling system, resulting in cost savings and environmental benefits.

-

• Reduced Waste EmissionsThis system not only reduces waste generation and emissions but also promotes environmental sustainability.

-

• Improving Production Efficiency and Environmental ConsciousnessThis recycling model boosts production efficiency and demonstrates the company's dedication to protecting the environment and conserving resources.

By implementing innovative environmental protection and resource recycling practices, TA talent Industries Co., Ltd. establishes a new standard for environmental sustainability in the manufacturing sector. By implementing an effective scrap iron recycling system, the company has successfully decreased the need for new pig iron, resulting in cost savings and environmental benefits.

TA talent Industries Co., Ltd., an advanced manufacturing enterprise in Changhua County, Taiwan, is reshaping the future of industrial manufacturing through its significant focus on automation and intelligent production. The company understands the significance of automation in enhancing production efficiency and supporting environmental sustainability. Presented are various innovative strategies and best practices in smart manufacturing:

-

• IoT Remote Monitoring SystemsEnable management to remotely oversee the production process and precisely track productions via data records. By improving production efficiency, the consistency of product quality is enhanced, guaranteeing that customers receive products of the highest standards.

-

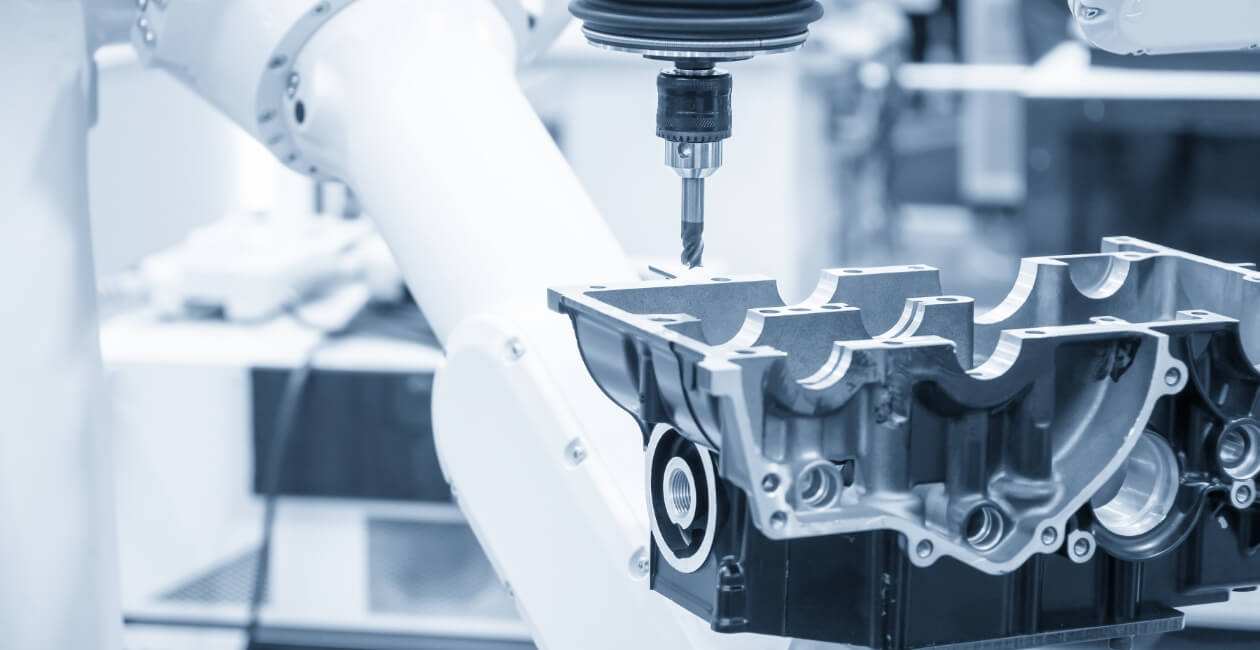

• Automation and Robotic Arm TechnologyTA talent Industries heavily relies on robotic arms for automated loading and unloading processes on its production lines, leading to a notable decrease in labor needs and a boost in operational efficiency. Implementing this automation technology minimizes resource waste from errors and enhances workplace safety for employees.

-

• Smart Fault Prediction and Maintenance SystemsWith advanced data analysis technology, TA Talent Industries can timely identify potential equipment failures and perform preventative maintenance. This not only reduces equipment downtime but also ensures the continuity and efficiency of the production process.

-

• Energy-Efficient Production EquipmentThe company also focuses on using energy-efficient production equipment, like improved melting furnaces, to achieve higher production efficiency with lower energy consumption. The use of this energy-saving equipment significantly reduces the company's carbon footprint and production costs.

-

• Flexibility in Mixed-Line ProductionTA Talent Industries' production lines can handle multiple products simultaneously, greatly improving production flexibility and the ability to respond to market changes.

Overall, the efforts of TA Talent Industries Co., Ltd. in intelligent automated production not only reflect its commitment to improving production efficiency and product quality but also demonstrate a deep understanding of environmental protection and sustainable development. These innovative practices make it a trustworthy and respected choice for potential buyers concerned about environmental impact and seeking efficient production partners.